Pneumatic lining control valve

Pneumatic lining control valve

Body material: WCB, 304, 316, 316L

Spool material: 304, 316+STL\PTFE

Seat material: 304, 316+STL; PTFE

Connection: flange, thread, welding

Seat form: single seat, two seat, sleeve

Valve cover type: standard type, low temperature type, heat dissipation type, bellows sealed type

Pneumatic actuator: multi spring film actuator

Pneumatic accessories: Electrical positioner, air filter, relief valve, hand wheel, retaining valve

[Essential information]

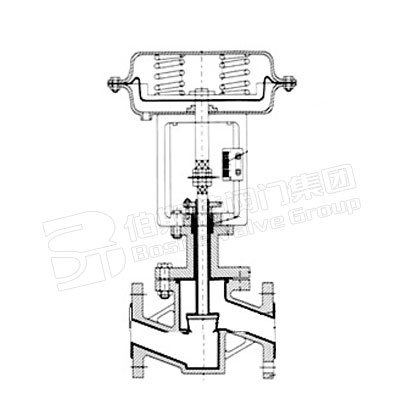

Operation principle: the lining valve is composed of a lining valve, a valve body component and a straight stroke pneumatic multi spring film actuating mechanism. The pneumatic actuator has two kinds of forms, when the air pressure is increased, putting out the film room called positive effect, with the valve components air to close; when the air pressure increases, putting back into the film room called the reaction, with the valve component gas open. The working principle of the electro pneumatic valve positioner: when the input signal pressure film room, produce thrust on the diaphragm compression spring, the plunger moves to drive the stem, change the flow between the spool and valve seat area, thrust reaction and signal pressure until the spring on the membrane phase equilibrium, so as to achieve the purpose of automatic adjustment process parameters.

[Valve structure drawing]

[Technical parameter]

| Nominal diameter(DN) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 150 |

| Seat diameter(dn) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 150 |

| Rated flow coefficient(KV) | 5.0 | 8 | 12 | 20 | 32 | 50 | 70 | 100 | 240 |

| Allowable pressure difference(MPa) | 3.8 | 3.2 | 3.0 | 2.0 | 1.8 | 1.5 | 1.4 | 1.0 | 0.6 |

| Nominal pressure(MPa) | 1.6、2.5、4.0、6.4 | ||||||||

| Rated stroke(mm) | 16 | 25 | 40 | 60 | |||||

| Equipped with actuator type | ZHA/B-22 | ZHA/B-23 | ZHA/B-34 | ZHA/B45 | |||||

| Spool form | Single seat plunger type fluorine lining valve core | ||||||||

| Flow characteristics | Quick opening characteristic | ||||||||

[Valve features]

1, Corrosion resistance is good: the valve body cavity, spool, valve seat, are lined with 3mm thickness of poly fluorine ethylene propylene, strong resistance to corrosive fluids.

2, Good sealing performance: PTFE bellows and packing double seal.

3, Leakage is small. As the valve core and seat adopt soft seal, ensure no leakage.

4, High precision adjustment: the use of fine small pneumatic actuators and electric actuators, small size, light weight.

[Adaptive condition]

Pneumatic fluorine valve assembly, the inner wall of the valve body in contact with the fluid and valve are high-pressure injection molding process, lined with corrosion and aging of FEP (F46), and the use of PTFE bellows seal. Widely used in acid, alkali and other strong corrosive media and toxic, volatile and other gases, liquid control.