Fluorine lined swing check valve

Fluorine lined swing check valve

Nominal diameter: DN25~400mm

Nominal pressure: 1.0~2.5MPa

Main material: cast steel, stainless steel and so on

Applicable temperature: -20~+120℃

Design standards: GB/T12235, GB/T12236

Connection standards: GB/T 9113, JB/T 79, and HG/T 20592

[Essential information]

Fluorine check valves are used in various concentrations of sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acid, strong oxidizing agents, the use of strong organic solvents is also suitable for various concentrations and other pipeline corrosive gas and liquid medium. Fluorine check valve is to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, lined with fluorine check valve for low flow rate and flow of large diameter changes are not often occasions. The disc of the valve is in a disc shape and rotates around the rotating shaft of the valve seat passage, and the flow resistance is smaller than that of the butterfly butterfly valve because of the linear flow in the valve passage.

[Standard parameter]

| Design standard | GB/T12235、GB/T12236 |

| Structural length | HG/T3704-2003 GB/T12221 ASME B16.10 |

| Connection standard | GB/T 9113、JB/T 79、HG/T 20592 |

| Pressure test | GB/T 13927、API598 |

| Pressure temperature rating | GB/T12224 |

[Valve features]

1, The fluorine check valve without any additional energy devices, reduce operating costs.

2, Suitable for general conditions and wear or corrosive medium of special conditions.

3, Unique design features allow solid particles to flow smoothly through the valve, and even use the flexibility of the body to wrap solid particles to ensure sealing.

4, Anti backflow, good effect, the use of rubber itself and reverse the role of back pressure.

5, Reliable sealing, especially the new curved valve nozzle, to further increase the tightness, reduce leakage or no leakage.

6, The work through the internal and external pressure difference to naturally open and close, is a strong corrosive medium and power station desulfurization.

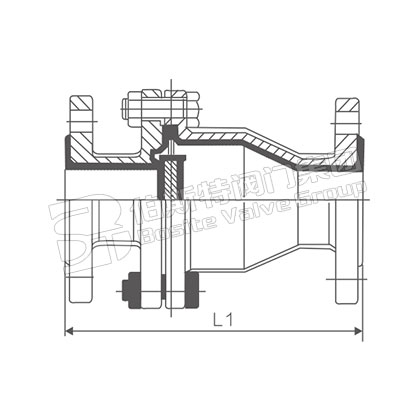

[Valve structure drawing]

[Adaptive condition]

Check valve installed in the pipeline system, the main role is to prevent media backflow, check valve is a kind of pressure on the media to open and close the automatic valve. The clip type check valve applies to nominal pressure PN1.0MPa~42.0MPa and Class150~25000; nominal diameter DN15~1200mm and NPS1/2~48; work temperature -196~+540℃ of various pipelines, used to prevent medium flow back. By choosing different materials, it can be applied to many mediums such as water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and uric acid.