Fluorine lining flange manual gate valve

Fluorine lining flange manual gate valve

Nominal diameter: PN16~PN25 (mm)

Nominal pressure: 0.6, 1, 1.6, Class150, JIS10K

Main material: cast steel, stainless steel, cast iron and so on

Applicable temperature: -25~180℃

Flange size: HG20592-97 ANSI B16.5a

[basic information]

Fluorine gate valve is manual, flange connection, Ming bar wedge rigid single gate, the valve seat sealing surface of PTFE material, nominal pressure PN16~PN25, valve body material is cast steel, fluorine plastic gate valve. Anti corrosion fluorine wedge gate valve used in various concentrations of -50 ~150 DEG C the flow of acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acid, strong oxidizing agents, the use of strong organic solvent FEP is also applicable to various concentration and other pipeline corrosive gas and liquid medium. The surface is uniformly coated with a layer of FEP. The channel of the valve body inner surface smooth, fluid resistance, high CV value, strong circulation, moderate torque, the use of four seal structure and elastic rubber gasket seat with SI in high temperature aging on the outside sealing surface, zero leakage medium.

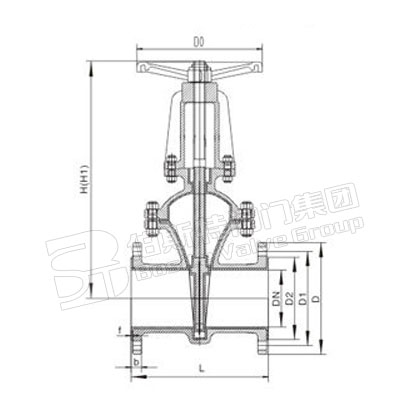

[Valve structure drawing]

[Standard parameter]

| Design standard | GB/T 12234、GB/T 12235 |

| Structural length | GB20592-97、ASME B16.10 |

| Flange size | HG20592-97 ANSI B16.5a |

| Pressure test | GB/T13927 API1598 |

[Valve features]

2, the closure speed is fast.

3, opening limit mechanism is convenient, flexible and precise.

4, small size, beautiful appearance.

5, simple operation, labor saving, convenient maintenance.

6, the fluid resistance is small, the sealing surface by medium erosion small.

7, medium flow does not love restrictions, not disturb flow, do not reduce pressure.

[Adaptive condition]

The valve products are specialized in petroleum, chemical, pharmaceutical, printing and dyeing, power, shipbuilding, metallurgy, military and other modern anti-corrosion engineering field.